The Power of Precision

Harnessing the Potential of Isotropic Bonded Magnets in Automotive Applications

In today’s rapidly evolving automotive industry, the demand for efficient and high-performance magnets is at an all-time high. As market dynamics constantly shift, companies like Magnequench (MQ) understand the importance of staying ahead by developing innovative solutions. By understanding the market dynamics and raw material cost considerations, Magnequench leverages its rich experience in jet-casting to develop cost-optimal alloy compositions to produce isotropic bonded powders (MQP™) to meet the stringent magnetic and thermal requirements of automotive applications.

MQ specializes in isotropic bonded magnets (MQ1™) production, combining bonded NdFeB powders (MQP™) with a binder material to produce magnets with unique properties and enhanced versatility. The dynamic blend of superior materials, engineering precision, and state-of-the-art manufacturing processes drive MQ’s core product offerings. Nonetheless, what sets Magnequench apart is its unwavering dedication to meeting customers’ needs. We see ourselves not just as a supplier, but as a trusted partner to our customers, collaborating to bring bespoke solutions to reality.

Isotropic bonded NdFeB (MQ1™) magnet-based motors have gained popularity in automotive accessory applications as they offer substantial weight and size reduction advantages and efficiency improvement over traditional ferrite-based motors. This efficiency directly translates into less energy consumption. When paired with renewable electricity generation, this can significantly reduce CO2 emissions on a well-to-wheel basis.

MQ1™ offers several distinct advantages. Its high magnetic strength and resistance to demagnetization allow for the design of high-torque motors. MQ1TM magnets also exhibit excellent thermal characteristics, maintaining their performance over a wide temperature range. This makes them suitable for automotive applications, where motors can experience significant temperature fluctuations. Furthermore, the possibility of magnetizing these magnets in complex patterns enables the development of motors with advanced performance characteristics.

In the realm of permanent magnet machines, such as permanent magnet brushless DC (PMBLDC), permanent magnet brushed DC (PMDC), and permanent magnet synchronous (PMSM) machines, the magnetization pattern and magnetic strength of the magnet affect the airgap flux waveform and its magnitude. This affects motor performance parameters like developed torque, efficiency, cogging torque, and torque ripple.

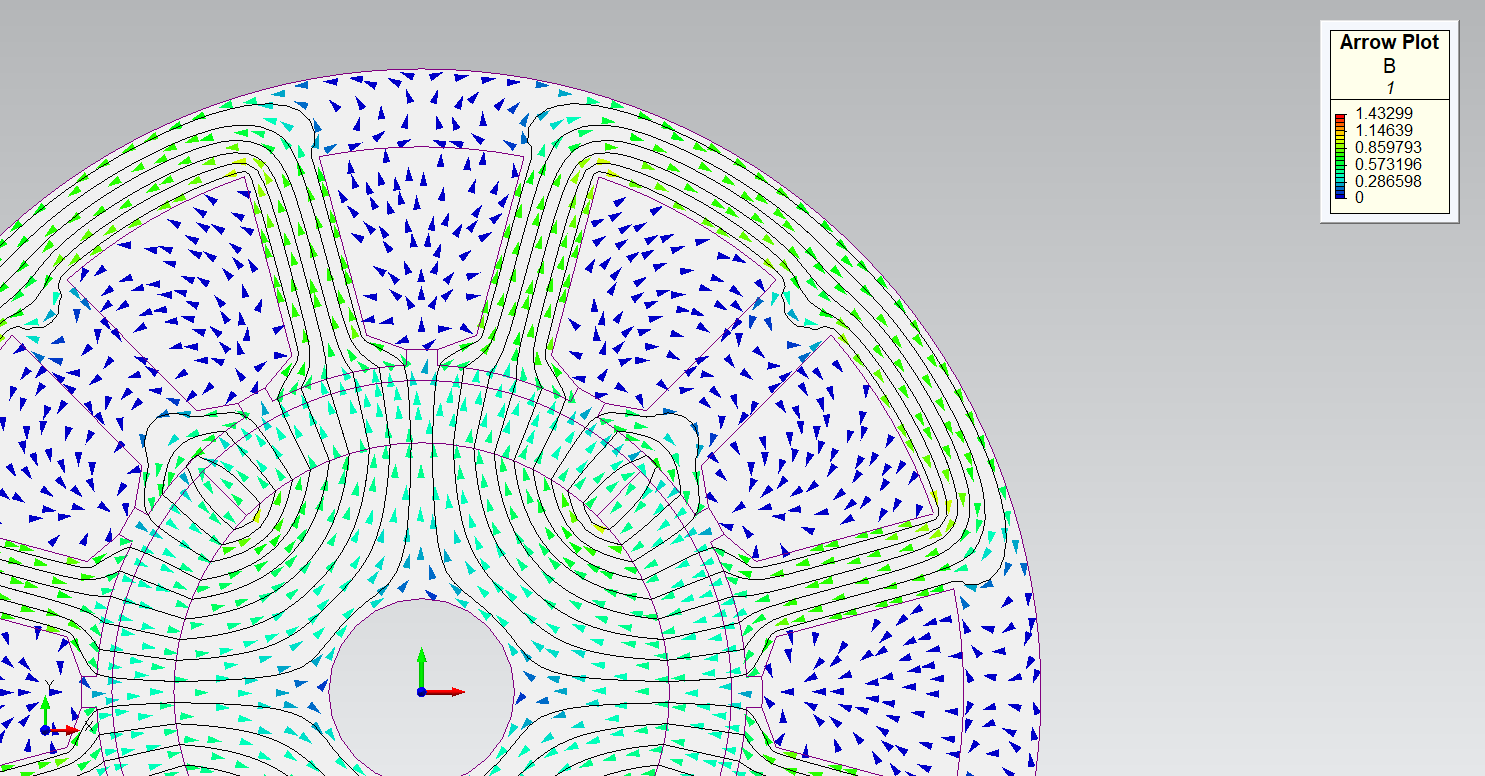

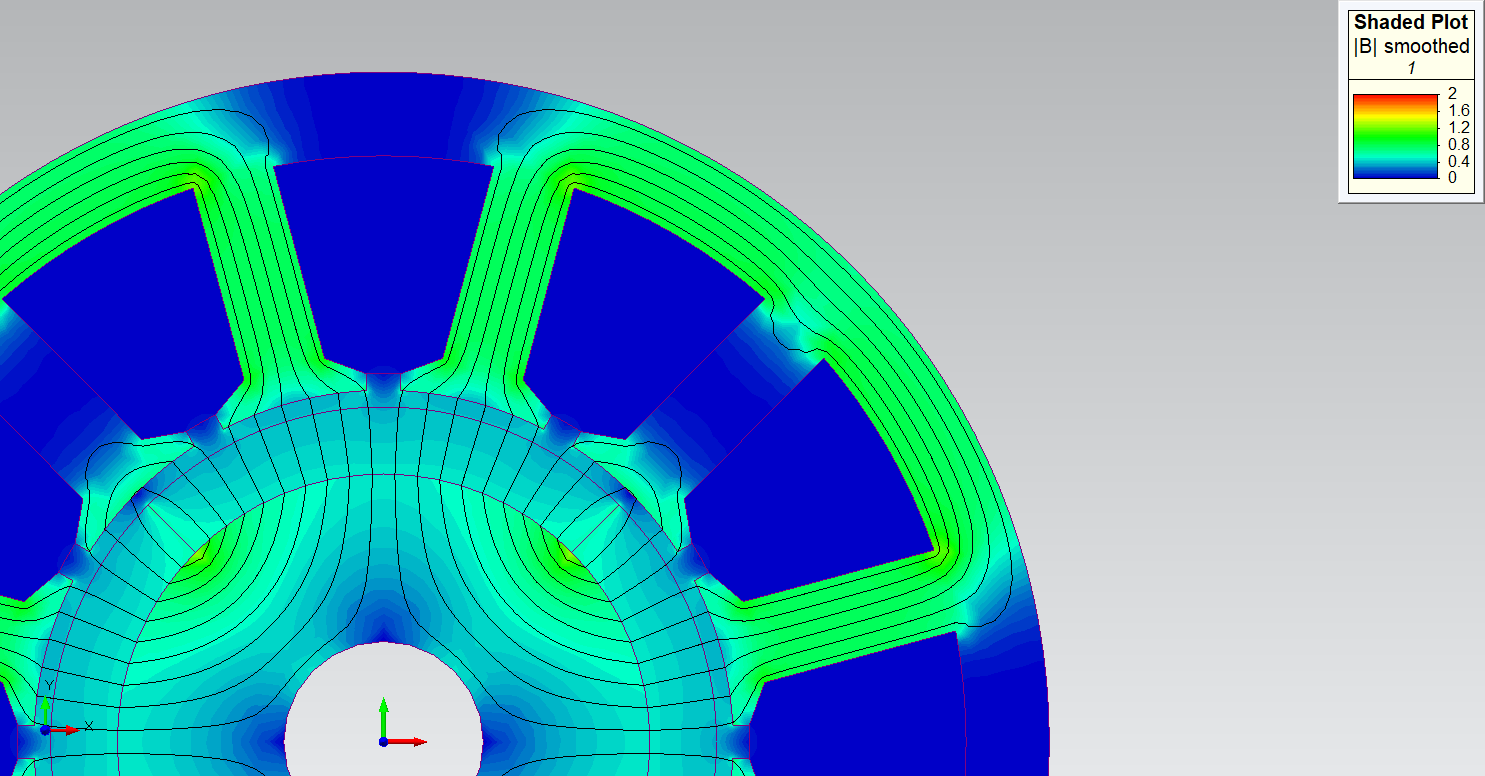

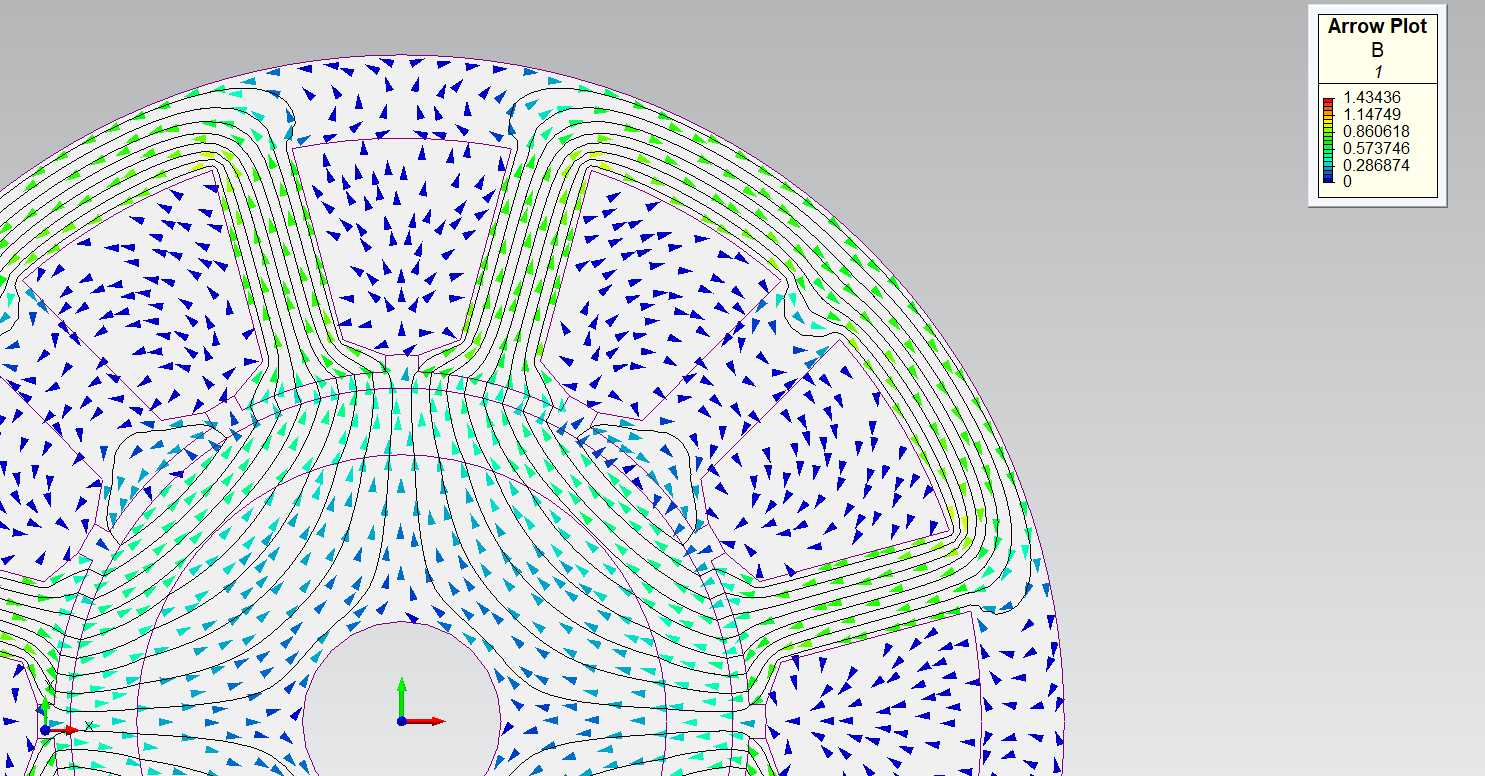

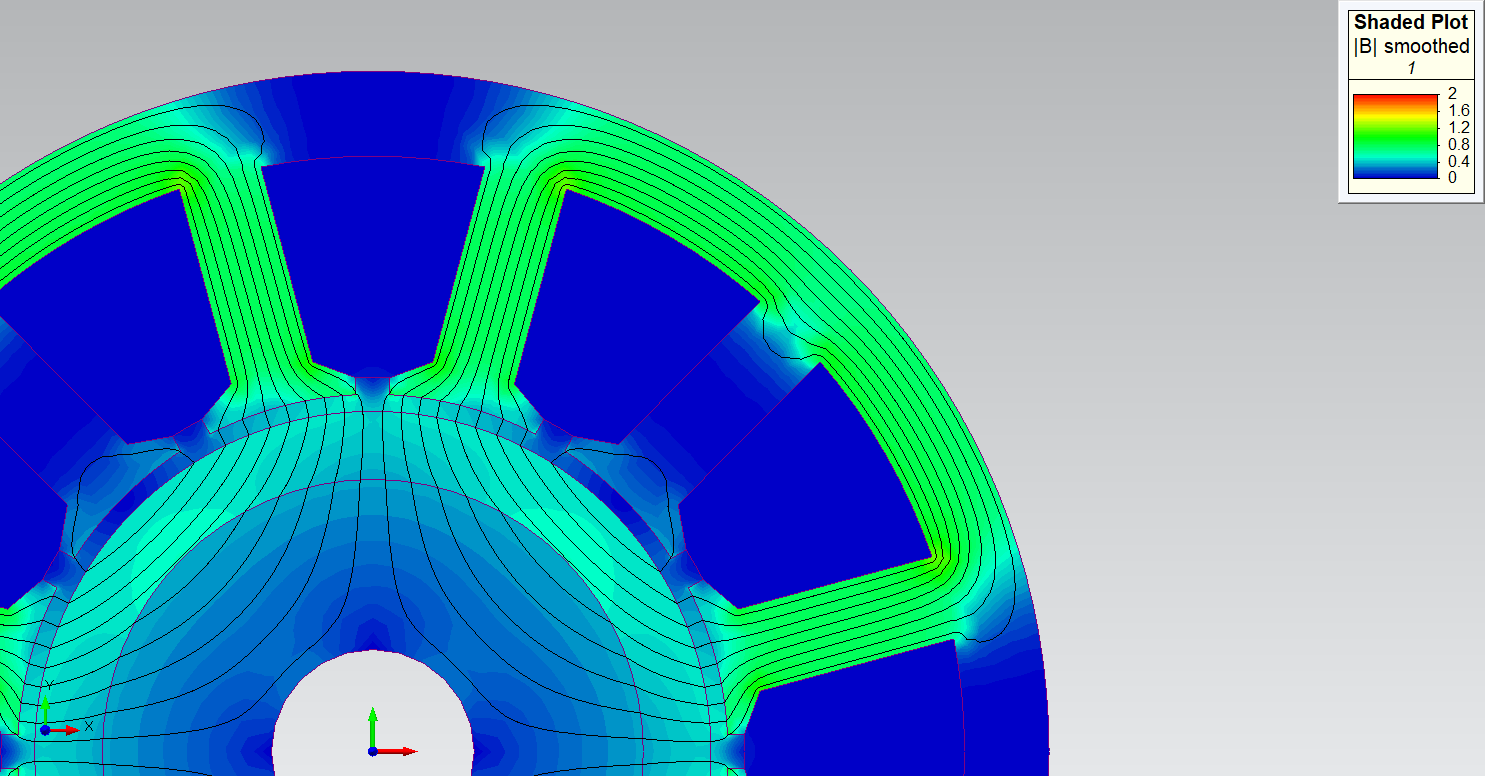

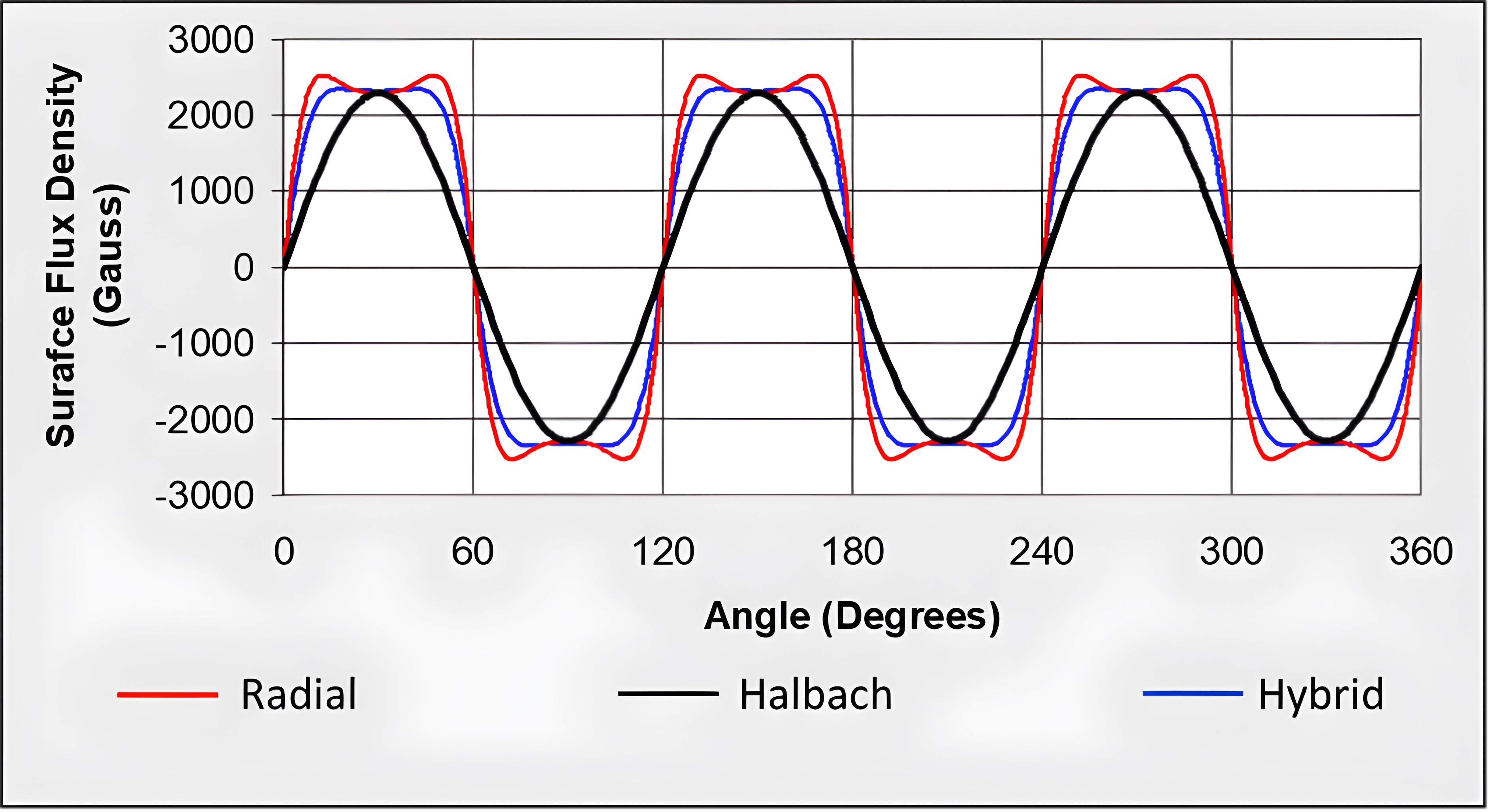

The MQ1™ magnet offers a unique advantage; whereby designing an appropriate magnetization fixture, different magnetization patterns can be achieved on the same magnet. MQ1TM magnets are popularly magnetized for three patterns: (i) Radial – resulting in rectangular airgap flux density waveform; (ii) Halbach – resulting in sinusoidal airgap flux density waveform, and; (iii) Hybrid – the airgap flux density waveform will be in between rectangular and sinusoidal. The selection of a target magnetization pattern is an important motor design criterion; a proper match between the drive strategy and flux pattern is crucial to harness the full potential of the magnets. For example, a square wave drive will provide the maximum torque when combined with a radially magnetized magnet.

Radial Magnetization:

For a low number of poles (e.g., 4-poles), radial magnetization guarantees the maximum flux per magnet volume, resulting in higher developed torque or, for the same torque, the lower current drawn from the supply compared to other magnetization profiles. The major drawback of using radial magnetization is the increased cogging torque and torque ripple, potentially leading to higher noise and vibration.

Halbach magnetization:

Offers higher airgap flux when the number of poles is high and/or the magnet is thick. The high number of poles with thicker magnets reduces the pole-to-pole leakage and offers higher airgap flux. Halbach magnetization also offers lower cogging torque compared to radial magnetization. Using sinusoidal control with halbach magnetization can result in low torque ripple, noise, and vibration. Applications like automotive accessory motors in the passenger compartment, handheld devices, and surgical tools that require the lowest cogging torque and torque ripple would prefer halbach magnetization.

However, achieving a sinusoidal airgap flux profile with anisotropic magnets like sintered NdFeB is challenging. It usually requires implementing skew on the stator/armature or magnet/rotor, which can complicate automatic winding or increase magnet cost due to lower yield.

Hybrid magnetization:

Offers an airgap flux density profile between radial and halbach. The air gap flux density profile is tuned to eliminate the specific harmonics from the airgap flux density, the developed torque, and the cogging torque. The elimination of these specific harmonics helps in achieving the reduction in motor noise and vibration.

Understanding the magnetization and magnetization fixture design process is critical to matching the simulated and actual motor performance closely. When designing a motor, the design software requires a designer to input the magnetization expected in the motor’s magnets. As the magnetization process is complex and difficult to predict, designers typically make assumptions about magnetization. These may sometimes be misguided and lead to significant differences in the expected and actual performance of the motor. A drive designer might assume Halbach magnetization and be disappointed with the motor’s performance after the magnetizing fixture delivers a pseudo-Halbach or hybrid orientation.

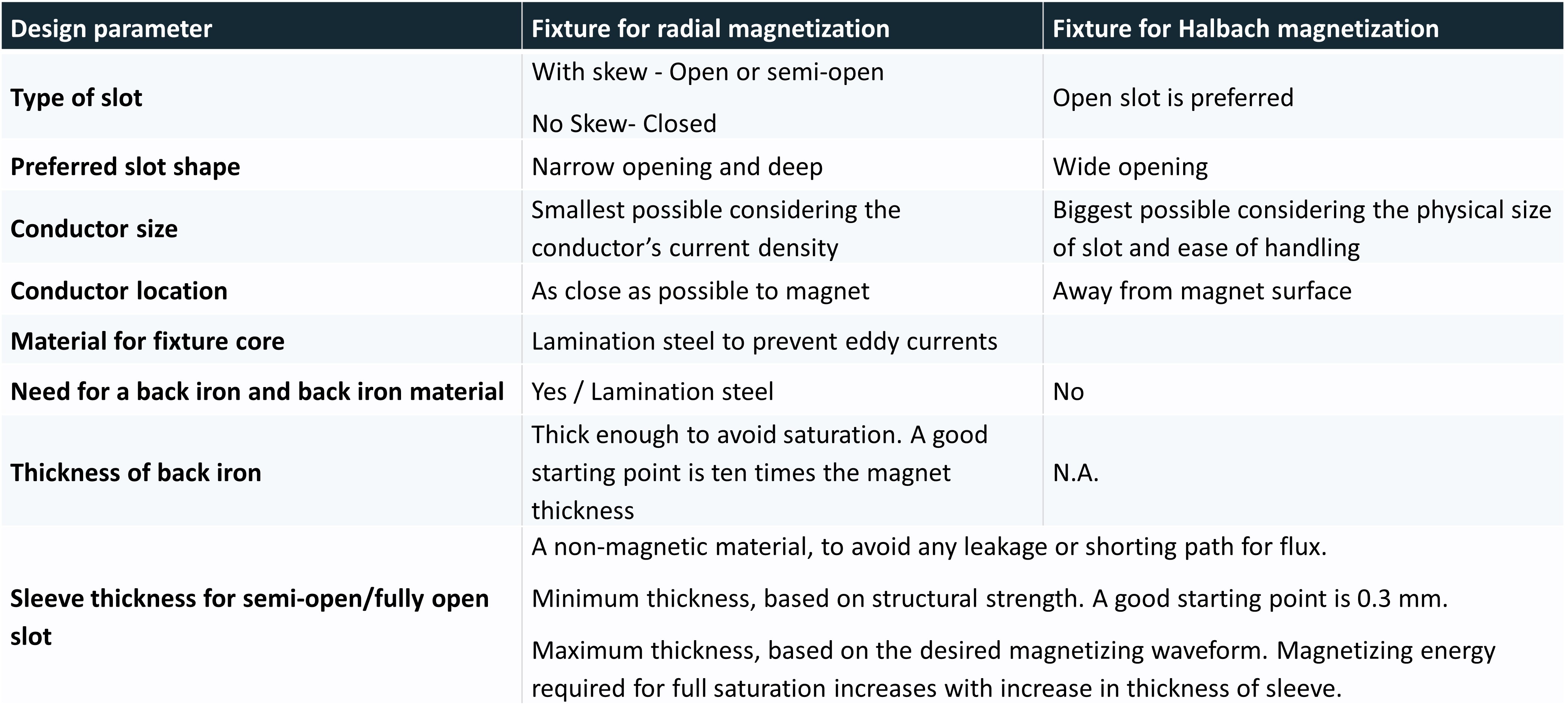

Designing the magnetization fixture and estimating the magnetization profile using finite element analysis is critical in bridging the gap between designers’ assumptions and reality. A magnetization fixture design is both an art and a science, involving decisions like magnetization energy required based on magnet type, size and location of conductor, number of turns/slot, and use of back iron during the magnetization process. It is very important to achieve a fully saturated magnet, as a partially saturated magnet results in lower airgap flux, lower motor performance like back-emf, developed torque, stall torque, and efficiency. The partially magnetized magnets are also more susceptible to demagnetization and leads to a higher flux loss at elevated temperatures. Table-1 summarizes the key considerations for magnetization fixture design to achieve radial or Halbach magnetization profile.

Magnequench has driven the development of the first finite element magnetization solver. The application team at Magnequench possesses decades of experience in designing the magnetization fixture and modelling the magnetization process. Utilizing the results from the finite element software to represent the magnetization in magnets is more accurate than estimation or empirical methods. This helps in more accurate motor performance prediction, leading to a shorter development cycle and cost.

In conclusion, isotropic bonded magnets (MQ1™) are key components in our technology-driven world, offering a range of benefits from low-cost production to excellent magnetic performance. Magnequench takes pride in its position at the forefront of advancing and perfecting this essential technology. Our extensive knowledge and experience in MQ1™ magnets and their magnetization systems, coupled with finite element analysis, allow us to match simulated and actual motor performance. By leveraging our know-how, we can shorten the development cycle of new or running motor programs.

Reach out to Magnequench experts to understand how we can collaborate; expert@magnequench.com