MQ1 Magnet Selection: Achieving Cost-Optimal Motor Designs

Isotropic bonded NdFeB magnet (MQ1™) offers several unique advantages in various applications. These advantages include being heavy rare earth free, providing high yield in near net shape magnet production, allowing tailored magnetization profiles for optimal magnet performance due to its isotropic nature, and exhibiting high resistivity to eliminate eddy current loss in magnet. MQ1™ magnets also exhibit excellent thermal characteristics, maintaining their performance across a wide temperature range. These features make them particularly suitable for demanding applications like automotive accessories and home appliances, where motors can either experience significant temperature fluctuations and/or require superior energy efficiency.

Which Grade is Optimal?

There are a wide range of MQ1™ magnet grades; hence, for any new design, the first question a designer has is this: which grade of magnet should I choose to arrive at cost optimal motor?

Several elements should be taken into account when choosing the magnet grade for a new design. The affordability and dependability of raw materials, the magnetic properties at both room and high temperatures, along with the magnet’s stability, specifically the potential for flux loss at high temperatures — all of these are important factors to consider.

Impact of Raw Materials

Fluctuations in the pricing of raw materials inevitably impact the cost stability of NdFeB magnets. As the originator of the raw material for the MQ1™ magnet, Magnequench possesses a profound understanding of rare earth materials and their consequential effects on the total magnet costs. Our dedicated technical teams are constantly at work, innovating new technologies and optimizing compositions to mitigate the impact of these price fluctuations. Moreover, we forge strategic partnerships with various tiers of automotive suppliers and home appliance manufacturers. Our aim is to ensure that they attain maximum performance from the MQ1™ magnet within their specified budget, thereby creating a harmonious balance between cost and efficiency.

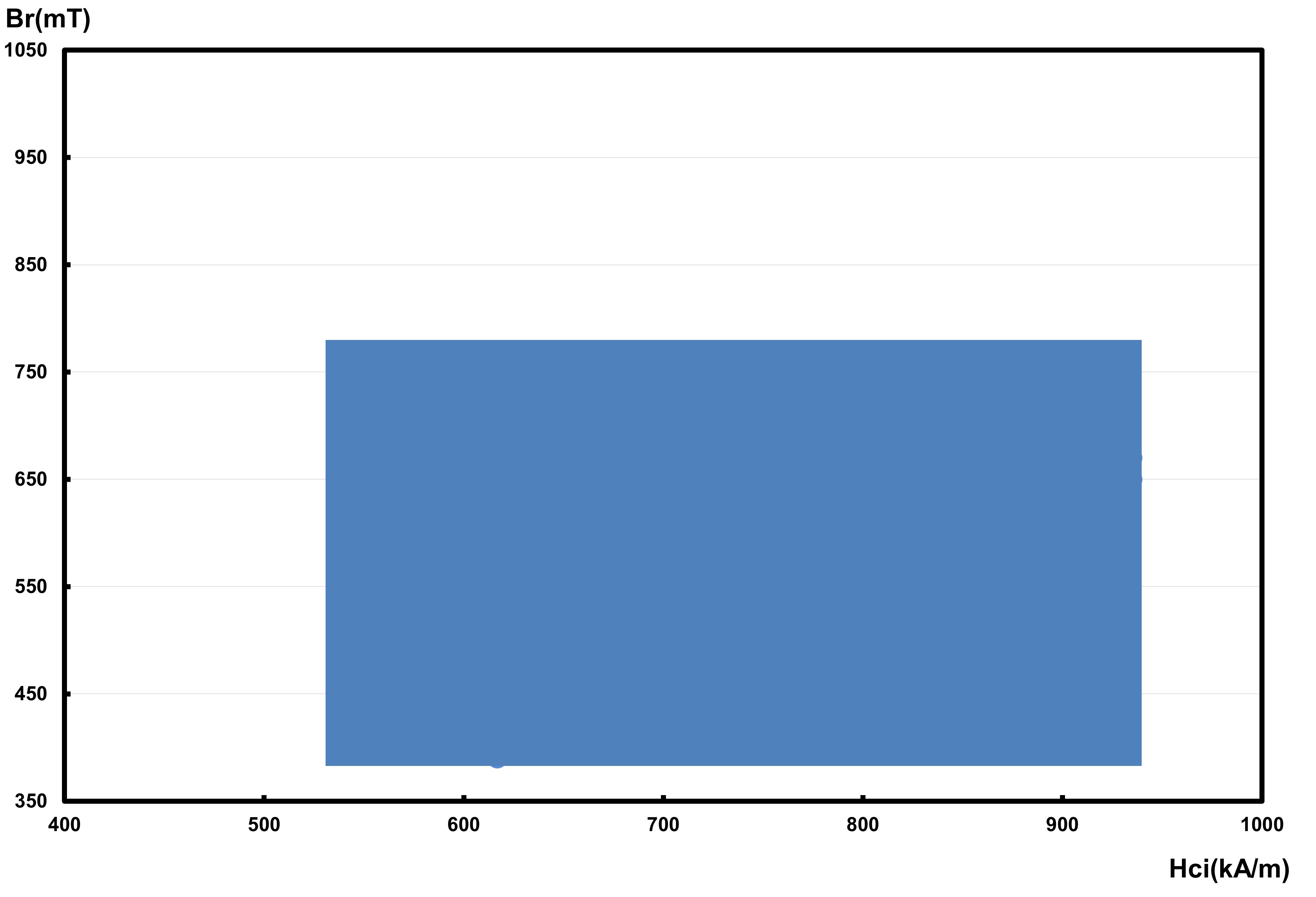

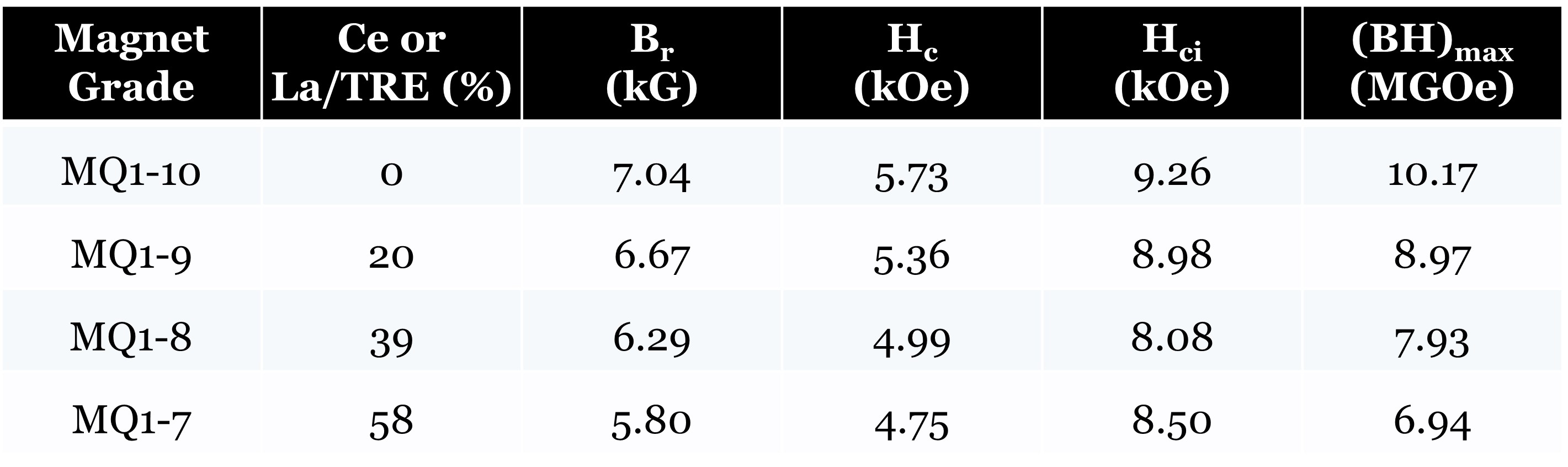

Figure 1 illustrates the magnetic properties that MQ1 magnets could achieve at room temperature. Magnequench offers cost-optimized MQ1™ magnet grades that replace higher-priced light rare earth (LRE) elements like Nd/NdPr with lower and stable-priced LREs like Ce/La — without a significant sacrifice in magnetics in both room and high temperature thermal properties. Table 1 presents the representative MQ1™ magnet grades. For an example, replacing almost 60% of total rare earth (TRE) by Ce/La results in only 18% reduction in magnet Br.

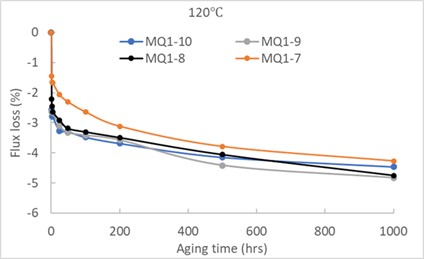

Figure 2 illustrates the flux loss at 120°C for representative MQ1™ magnet grades, indicating that magnets with Ce/La as part of the total rare earth (TRE) exhibit similar or even slightly better thermal stability compared to magnets with only Nd/NdPr as TRE.

Using a magnet with a slightly lower Br depends on the allowable motor size and weight. The use of the MQ1™-7 magnet in comparison to the MQ1™-10 magnet may lead to 10% to 20% increase in motor volume and weight. A magnet with Ce/La has slightly lower Hc; hence, a slightly thicker magnet is required to avoid the magnet operating point falling below the knee during the worst-case magnet operating condition (when the magnet sees the high temperature and the maximum demagnetization current). Even with a thicker and heavier magnet, the magnet with Ce/La content will still be the cost optimal design. This is because of lower and stable price of LREs like Ce/La.

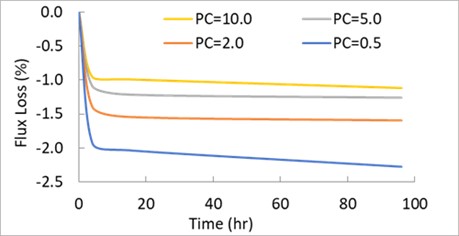

Maximum Allowable Flux Loss

It is also important to understand the allowable maximum flux loss for a motor under design. The flux loss data for magnets are measured with specific dimensions of a magnet (mostly Permeance Co-efficient (PC) = 2). However, the actual PC in motors is much higher than 2. Figure 3 shows the flux loss for magnet with different PC values. From Fig. 3, it can be observed that the magnet with higher PC offers much better thermal resistance and hence lower flux loss. The use of magnets that offer less than target flux loss (measured for PC=2) will lead to an unintended but significantly higher safety margin and an increased motor cost. On the contrary, selecting a magnet grade with slightly higher flux loss (for PC=2) than target, when used in motor, will meet the flux loss target in a motor. This helps in achieving the cost optimal design.

Linearity of Room and High-Temperature Magnetic Characteristics

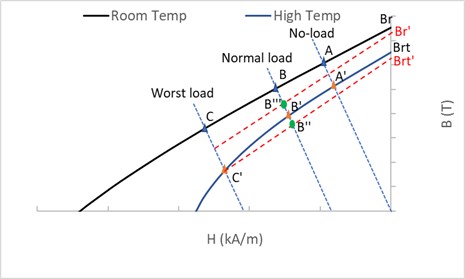

The PC of the magnetic circuit should be as high as possible to achieve the highest airgap flux. The magnetic characteristics of a magnet with PC of magnetic circuit form critical parameters in evaluating the potential of partial demagnetization at the maximum temperature that a magnet will experience during the operation of the motor. Figure 4 shows the magnet characteristics at room temperature and at elevated temperatures. The magnet has non-linear B-H characteristics at higher temperatures. Point A represents the magnet operating point at no-load and room temperature. At high temperatures, the no-load operating point moves to point A′. When the normal load is applied to a motor, armature/stator current induced field or mmf, moving the operating point to B at room temperature or at B′ at high temperature. Point, B′ is on the linear region of the high temperature B-H characteristics of the magnet. When the load is removed and magnet is at high temperature, the magnet recoils and the operating point moves to A′. On motor cooling back to room temperature, it will move back to A’. For the worst load condition, the operating point at high temperature will be at C′. As this point is below the knee point, when the load is removed the magnet recoils based on the recoil permeability and the normal load the magnet operating point will be B′′ instead of expected B′ . When the motor cools down to room temperature, the magnet operating point will be B′′, the load removal will bring back the magnet Br to Br′ due to irreversible demagnetization of the magnet. To avoid such irreversible demagnetization, it is important to select the magnet with linear magnetic characteristics at the maximum temperature a magnet can see during the working of motor.

Conclusion

Selecting the right magnet grade is crucial for achieving cost-optimal motor designs. With Magnequench’s expertise in isotropic bonded NdFeB magnets, including our innovative MQ1™ magnets, we are committed to helping our customers make informed decisions. With decades of experience, our technical teams collaborate closely with automotive and home appliance manufacturers to design magnetic circuits, help them select the most suitable magnet grades, and optimize motor performance. By leveraging our knowledge of raw materials, magnetic characteristics, and stability, we ensure our customers receive cost-effective solutions without compromising quality or efficiency. Partnering with Magnequench means gaining access to cutting-edge technology, reliable support, and the expertise needed to propel your motor designs forward in today’s rapidly evolving landscape.

Contact us today or drop an email expert@magnequench.com the information above. Let us help you achieve cost-optimal motor designs with our exceptional isotropic magnets and precision magnet assemblies.