Automotive

Magnequench, originally founded by General Motors in the mid 1980’s, has a long history of serving the automotive industry.

Magnequench actively collaborates with Tier 1 and Tier 2 suppliers to design cost-optimized lightweight and compact electric motors. Bonded neo magnets (MQ1™) provide superior magnetic performance relative to conventional (ferrite) magnets and are commonly found in passenger compartment (accessory) motors used in seats, trunk lifts, doors, and windshield wipers, as well as in pumps, fans, and sensors located under the hood of the car.

Magnequench’s fully dense hot formed magnets (MQ3™) provide the same performance as sintered NdFeB magnets with zero or minimal heavy rare earth elements. MQ3™ magnets are commonly found in electronic power steering actuators and hybrid electric vehicle traction motors.

In order to serve various design requirements for automotive industry, Magnequench has a highly skilled team of design engineers and research scientists to provide customer support during the initial stages of design and development of concepts and prototypes, hastening the customer’s time to market. Some examples where MQ1™ magnets are used to provide superior performance as compared to conventional magnetic materials are shown below.

Reduced weight and size

The automotive market demands increased functionality and comfort in the passenger compartment, which leads to an increase in the numbers of motors needed within the finite space of the passenger compartment. Moreover, while the number of motors and functions proliferates, weight concerns become paramount. Because of these two effects, MQ1™ magnets are the preferred choice due to their ability to make smaller and lighter motors. An example below shows that by designing a motor with MQ1™ magnets, application engineers can achieve a weight reduction of nearly 40% with a size reduction of almost 36%.

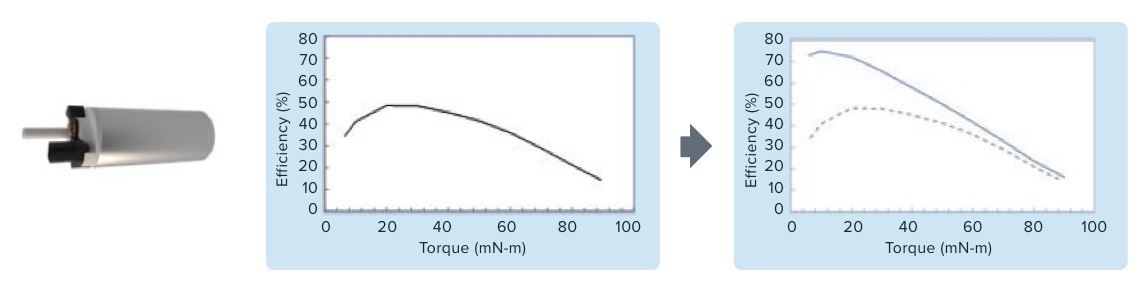

Improved efficiency

For continuous duty applications like a fuel pump, the pump motor is required to withstand prolonged load conditions. MQ1™ magnets can provide crucial performance improvements required for this continuous use. Improvement in fuel pump performance directly results in improved fuel efficiency.

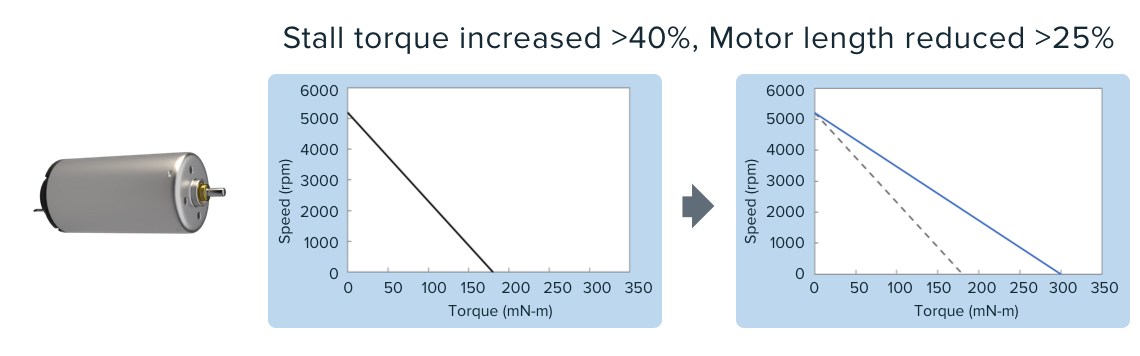

Improved performance

Another example of MQ1™ magnets providing additional value in the automotive industry is trunk lift motors. Magnequench engineers collaborate with tier 1 and tier 2 suppliers to design motors using MQ1™ magnets. These motors demonstrate higher stall torque as well as highly efficient operation in a reduced size envelope.

At Magnequench, we work with magnet users to design novel magnetic solutions and to ensure those solutions are executed and supplied with the highest quality.