Case Study: MQ1 Magnets for High Speed Vacuum Cleaners

The high-speed motor market encompasses both traditional and emerging home appliances, such as vacuum cleaners, hair dryers, and robot cleaners, with motors operating at speeds exceeding 100,000 rpm. Some of the challenges in the design and manufacture of these high-speed motors include rotor power losses, mechanical strength of magnets, and imbalanced radial forces in the rotor.

Magnequench has engineered a unique powder and compound, specifically designed for applications requiring high mechanical strength. Our highly integrated production process further enhances the mechanical strength of our MQ1™ magnets, making them ideal for high-speed motor applications like those found in vacuum cleaners.

With our materials engineering and motor design expertise, Magnequench puts forward a design that uses a 3S2P MQ1 magnet as an alternative to the 3S2P sintered design to address the above challenges. This MQ1™ magnet features an outer diameter of 8.2mm, an inner diameter of 3.0mm, and a height of 10.0mm, with a suggested air gap reduction from 0.8mm in sintered magnets to 0.3mm for MQ1™.

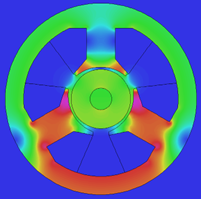

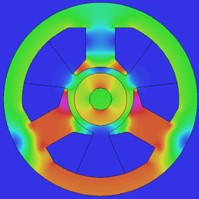

|

|

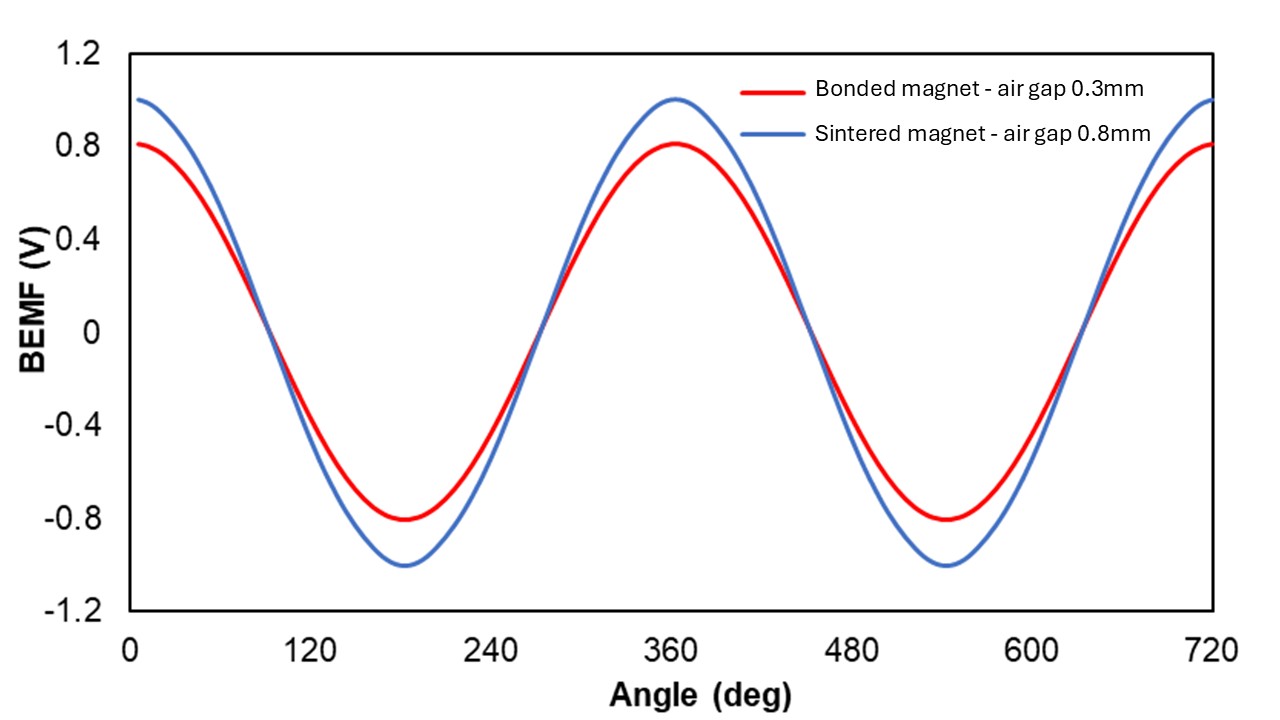

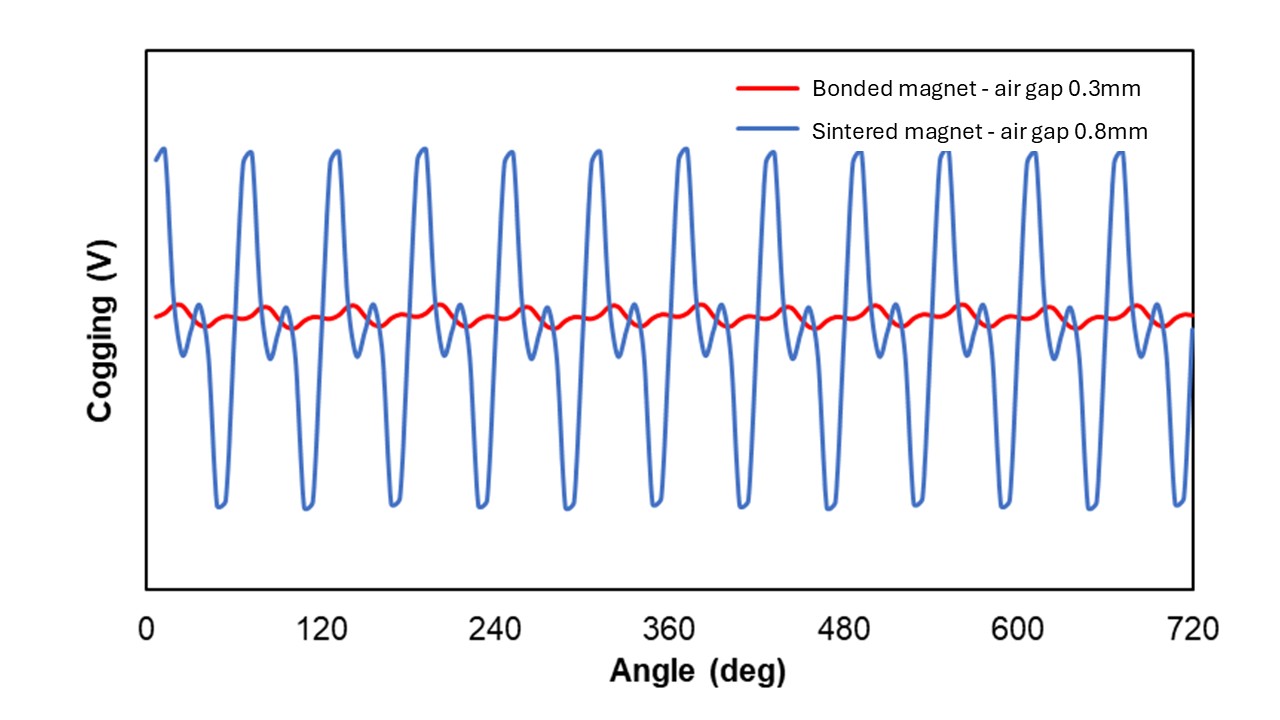

With our advanced simulation capabilities and rich experience, Magnequench optimized the target magnetic field distribution and the back electromotive force (BEMF) of the MQ1™ motors compared to the sintered magnet motor. With MQ1™ magnets, the motor can achieve a BEMF amplitude of 81% compared to the sintered motor and a significantly smaller cogging torque.

To compensate the slight reduction in the BMEF, Magnequench adjusted the motor winding designs to ensure the overall BMEF remained the same as that of the sintered design. This step was pivotal in maintaining comparable motor output and efficiency. The final test results show that the efficiency of high-speed fans with MQ1™ magnets (motor + blades) is very close to that of sintered ones (49% vs. 50%).

Magnequench has successfully addressed critical design challenges like cogging torque and achieved comparable efficiency in high-speed motor applications with MQ1™ solutions. Choose Magnequench to leverage cutting-edge bonded magnet technology. Reach out to Magnequench experts at: sales@magnequench.com